The growing adoption of industrial Ethernet in manufacturing has posed new challenges in ensuring its reliability and operational continuity. Unlike conventional Ethernet, industrial Ethernet must withstand extreme environmental conditions, which can severely compromise the operation of network devices. Designing and implementing highly reliable industrial Ethernet networks therefore requires an innovative approach that goes beyond the standard requirements of traditional IT.

Network components, particularly industrial Ethernet switches, must be specifically designed to operate in hostile environments, ensuring the performance and resilience required for critical automation and control applications. Only through careful device selection, advanced configuration of network parameters, and integration with operations management (OT) systems can the reliability and efficiency of data transmission required in modern industrial plants be ensured.

Industrial Ethernet: What It Is and What Are the Challenges for Reliable Design

Industrial Ethernet refers to specially designed network devices typically switches, media converters, and wireless access points for use in harsh environments outside of normal IT conditions. Unlike standard Ethernet, industrial Ethernet uses additional protocols to ensure accurate and timely data delivery, even in the presence of extreme environmental conditions such as temperature, humidity, vibration, and electromagnetic interference.

Critical applications require highly reliable and precise data transmission, which led to the creation of Industrial Ethernet (IE). IE devices are therefore designed to survive excessive temperatures and harsh environments, including dust, humidity, vibration, and electrical interference.

The design and implementation of industrial networking systems must therefore address many challenges to ensure reliability and efficiency in industrial Ethernet networks.

Industrial Ethernet Networks: Key Requirements for Reliability

In addition to data traffic management by switches, other key requirements for ensuring the reliability of industrial Ethernet networks include:

1. Robust components that are resistant to extreme environmental conditions, such as temperature, humidity, vibration, and aggressive chemicals. Devices must be specifically designed and certified to withstand these conditions.

1.1 Industrial devices must be able to operate in environments with high or very low temperatures, high humidity, constant vibration, and exposure to aggressive chemicals, such as oils, lubricants, and solvents. This requires particularly robust design and construction, using materials and components capable of withstanding these harsh environmental conditions.

It is important that devices are tested and certified to ensure the performance and reliability required in such extreme industrial environments.

2.Support for industrial automation and control protocols, to enable integration with operations management and monitoring (OT) systems.

2.1 Industrial devices must be able to communicate and integrate with the automation and control systems used in manufacturing plants. Protocols such as PROFINET and Modbus/TCP are widely adopted in industrial automation and allow devices to exchange data and information with Operational Technology (OT) management and monitoring systems. This compatibility and interoperability is crucial for easily integrating devices into existing automation infrastructures.

3.Direct current (DC) power supply, consistent with power sources commonly used in industrial environments.

3.1 In industrial environments, the main power sources are often direct current (DC), unlike residential and commercial electrical networks, which use alternating current (AC). This simplifies the installation and integration of devices into existing industrial electrical infrastructures.

4. Network design and implementation.

4.1 Industrial devices must be able to connect and communicate within automation and control networks. This requires careful networking system design to ensure reliable connectivity, adequate transmission speed, and the ability to integrate various industrial protocols. Building a robust and high-performance network infrastructure is essential for the integration and coordinated operation of all devices within the industrial environment.

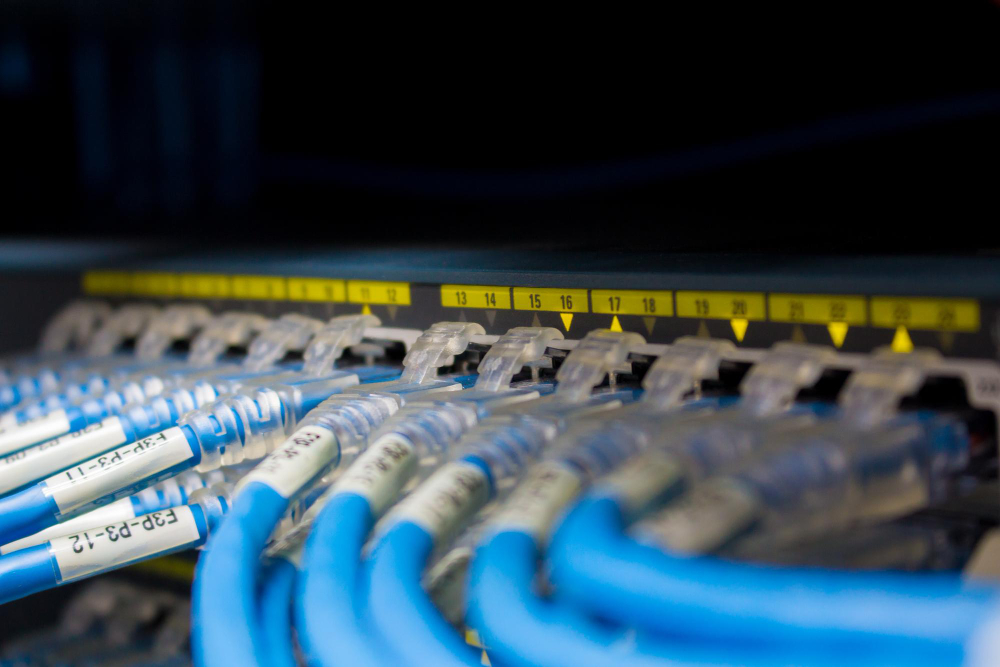

Industrial Ethernet Switches: Their Role in Data Traffic Management

Industrial Ethernet switches play a crucial role in managing data traffic in industrial Ethernet networks. Unlike consumer switches, industrial switches are designed to operate in extreme environmental conditions, ensuring reliability and optimal performance even in the presence of high temperatures, vibrations, humidity, and other factors that can compromise the proper operation of network devices.

Managed industrial Ethernet switches offer numerous advantages over unmanaged switches in terms of data traffic management and control. Thanks to advanced configuration features, these devices allow traffic to be prioritized based on the needs of different applications, ensuring the proper delivery of critical services. Broadcast domain segmentation through the use of VLANs helps optimize bandwidth utilization and improve network security by limiting the propagation of unwanted traffic.

Furthermore, managed industrial switches enable network monitoring and diagnostics, providing detailed information on link operation and performance. This traffic monitoring and analysis capability is essential for promptly identifying and resolving any issues, thus ensuring the reliability and business continuity required in industrial environments.

Industrial Ethernet switches therefore play a vital role in data traffic management, enabling the configuration, control, and monitoring of industrial Ethernet networks. These features are crucial for ensuring the reliability and performance required in industrial Ethernet applications and in the design and implementation of highly reliable networks.